Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

- ≤10,000pcs

- 10,000-50,000pcs

- 50,000-100,000pcs

- ≥100,000pcs

- mm

- inch

- cm

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

- Carbon Fiber

- Resin

- Nylon

- PLA

- ABS

- PETG

- TPU

- PC

- ASA

- PEEK

- PPS

- Aluminum

- Stainless steel

- Titanium

- Tool steel

- Aluminum

- Stainless steel

- Mild steel

- Copper

- PMMA (Acrylic)

- Carbon Fiber

- ABS

- POM

- Nylon

- Polycarbonate (PC)

- PC/ABS

- PVC

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- TPU

- ABS

- POM

- Nylon

- Polycarbonate (PC)

- PVC

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- TPU

- Rubber

Heat alert

Heat alert

To prevent parts with easily deformable structures from deforming during transportation, as the gradual increase in weather temperature.

1. It's recommended to use the following Resin models with good heat resistant and strength: Somos® Ledo, Somos® Taurus, Somos® Perform, UTR 8220, UTR Flex, UTR Therm.

2. Wall thickness is thicken into ≥2mm.

Deformation warning (For non-metal parts with easily deformable structure)

Deformation warning (For non-metal parts with easily deformable structure)

Non-metal parts with easily deformable structure would occasionally deform when squeezed by external force during transportation.

1. For those who choose Resin materials, it's recommended to use the following Resin models with good heat resistant and strength: Somos®Ledo, Somos®Taurus, Somos®Perform, UTR 8220, UTR Flex, UTR Therm.

2.Wall thickness is thicken into ≥2mm.

3.Nylon is preferred over resin for parts with easily deformable structure.

4.Deformed parts can be corrected by heating process, like using hot air gun or hot water.

-

Aluminum 6061

Aluminum 6061

Aluminum 6061 is the most popular aluminum alloy. It has good strength-to-weight ratio, excellent machinability and natural corrosion resistance.

-

Aluminum 7075

Aluminum 7075

Aluminum 7075 is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels.

-

Aluminum 5052

Aluminum 5052

Aluminum 5052 is a strain hardening aluminum alloy with excellent corrosion resistance. Suitable for marine applications. Can be welded.

-

Aluminum 2A12

Aluminum 2A12

Aluminum 2A12(Al-Cu-Mg ) is the hard alloy, its composition is more reasonable and owns better overall performance.

-

Stainless steel 304

Stainless steel 304

Stainless steel 304 is the most common stainless steel. It is essentially non-magnetic steel and it is less electrically and thermally conductive than carbon steel.

-

Stainless steel 316/316L

Stainless steel 316/316L

The second most used stainless steel after 304, the general purpose austenitic stainless steel 316 has superior corrosion resistance particularly in chloride containing environments and good elevated temperature strength.

-

Stainless steel 303

Stainless steel 303

Stainless steel 303 has excellent toughness, but lower corrosion resistance than 304.

-

Stainless steel 430

Stainless steel 430

Stainless steel 430 is a non-hardenable steel containing straight chromium, and belongs to the ferritic group of steels.

-

Stainless steel 201

Stainless steel 201

Stainless steel 201, with certain acid and alkali resistance, high density, no bubbles, no pinholes, etc.

-

Brass C360

Brass C360

Brass C360 is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction.

-

Copper

Copper

Copper has good electrical conductivity, thermal conductivity, ductility, deep drawing and corrosion resistance.

-

Titanium Gr5 (TC4)

Titanium Gr5 (TC4)

Titanium Gr5 (TC4) is the most widely used titanium grade. It is a two phase a+ß titanium alloy, with aluminum as the alpha stabilizer and vanadium as the beta stabilizer.

-

Mild steel 1018

Mild steel 1018

Mild steel 1018 is a widely used alloy with good machinability, weldability, toughness, strength, but it’s susceptible to corrosion on the surface.

-

Mild steel 1045

Mild steel 1045

Mild steel 1045 is a medium tensile carbon steel with good strength and impact properties.

-

Mild steel A36

Mild steel A36

Mild steel A36 is the most commonly used mild and hot-rolled steel.

-

Alloy steel 4140

Alloy steel 4140

Alloy steel 4140 is a chromium-, molybdenum-, and manganese-containing low alloy steel.

-

Alloy steel 4340

Alloy steel 4340

Alloy steel 4340 is a heat treatable and low alloy steel containing chromium, nickel and molybdenum.

-

Alloy steel 1215

Alloy steel 1215

Alloy steel 1215 contains carbon as the significant alloying element. Small quantities of molybdenum, chromium, nickel, aluminium, and copper are present in these steels.

-

Tool steel D2

Tool steel D2

Tool Steel D2 is a versatile high-carbon, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromium-rich alloy carbides in the microstructure.

-

Tool steel A2

Tool steel A2

Tool Steel A2 is a versatile, air-hardening tool steel that is characterized by good toughness and excellent dimensional stability in heat treatment.

-

Tool steel O1

Tool steel O1

Tool Steel O1 is the original oil-hardening, “non-shrinking” tool steel that can be hardened to the Rockwell C 65 range from a low austenitizing temperature.

-

Tool steel A3

Tool steel A3

Tool Steel A3 is a high quality Cold work tool steel, It belong to the high quality high carbon alloy tool steel.

-

Tool steel S7

Tool steel S7

Tool steel S7 is a shock-resistant air hardening steel and has exceptional impact properties plus the highest hardenability of shock resisting grades of tool steel.

-

Tool steel H13

Tool steel H13

Tool steel H13 is widely used in hot and cold work tooling applications.

-

Spring steel

Spring steel

Spring steel is used prominently in automotive and industrial suspension applications.

-

ABS

ABS

ABS is tough, resilient, allows detailed moldings, and is non-toxic. It is known for its low cost and ease of machining, molding and even 3D printing.

-

ABS Flame Retardant

ABS-Flame-Retardant

ABS is tough, resilient, allows detailed moldings, and is non-toxic. It is known for its low cost and ease of machining, molding and even 3D printing.

-

Polycarbonate (PC)

Polycarbonate (PC)

Polycarbonate (PC) is a thermoplastic with high toughness, excellent impact strength and good machinability.

-

Nylon 6

Nylon 6

Nylon 6 is widely used engineering thermoplastic characterized by its high toughness and strength.

-

Nylon 12

Nylon 12

Nylon 12 is made from ω-aminolauric acid or laurolactam monomers that each have 12 carbons, hence the name ‘Nylon 12’. It is one of several nylon polymers.

-

Polypropylene (PP)

Polypropylene (PP)

Polypropylene (PP) is a thermoplastic polymer resin which has a tough, rigid and crystalline structure from a propene monomer. It’s the second most widely produced plastic (after PE) and is harder and more heat resistant than PE. It has many uses from commercial to industrial applications.

-

POM

POM

POM or polyoxymethylene is an engineering thermoplastic material, also known as acetal, Delrin, polyacetal or polyformaldehyde.

-

Teflon

Teflon

PTFE is an engineering thermoplastic with excellent chemical and thermal resistance and the lowest coefficient of friction of any know solid.

-

PMMA

PMMA

Polymethyl methacrylate, abbreviated as PMMA, is also known as Acrylic, Acrylic or Plexiglass. It has the advantages of high transparency, low price, and easy machining. It is a commonly used glass substitute material.

-

Polyethylene (PE)

Polyethylene (PE)

Polyethylene (PE) is the most common plastic in use today. It is a linear, man-made, addition, homo-polymer, primarily used for packaging.

-

PEEK

PEEK

PEEK is an engineering thermoplastic with excellent mechanical and thermal properties. Can be used to replace metal parts.

-

Bakelite

Bakelite

Bakelite is the first plastic made from synthetic components. It is a thermosetting phenol formaldehyde resin, formed from a condensation reaction of phenol with formaldehyde.

-

FR4

FR4

FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios.

-

Rubber

Rubber

Rubber is a highly elastic polymer material with reversible deformation. It is elastic at room temperature and can produce greater deformation under a small external force. It can be restored to its original shape after the external force is removed. Rubber is a completely amorphous polymer, its glass transition temperature (T g) is low, and its molecular weight is large.

-

Carbon Fiber Plate

Carbon Fiber Plate

Carbon fiber plate is a board made of carbon fiber prepreg, which can replace the use of steel and aluminum.

-

Standard white material (UTR 8360)

Standard white material (UTR 8360)

UTR 8360 is a high-precision photosensitive resin material with excellent dimensional accuracy, smooth surface and excellent detail performance.

-

UTR Imagine Black

UTR Imagine Black

UTR Imagine Black is a high-precision photosensitive resin material with excellent dimensional accuracy, smooth surface and excellent detail performance.

-

UTR-8100 (transparent)

UTR-8100 (transparent, Spray varnish)

UTR-8100 is a colorless and transparent material with proven dimensional stability, suitable for general-use, detailed modeling and transparent visual simulation.

-

PWR Dark Black

PWR Dark Black

PWR Dark Black is a high-precision photosensitive resin material with excellent dimensional accuracy,

-

UTR-8100 (translucent)

UTR-8100 (translucent)

UTR-8100 is a colorless and transparent material with proven dimensional stability, suitable for general-use, detailed modeling and transparent visual simulation.

-

Somos ® Ledo

Somos ® Ledo

Somos® Ledo is a photosensitive resin material with tough texture and excellent waterproof performance developed by DSM, which can be used to make precision parts for prototyping and functional testing.

-

UTR 8220

UTR 8220

UTR 8220 is suitable for high-precision SLA 3D printing rapid prototyping system with 355nm light source.

-

Somos ® Taurus

Somos ® Taurus

DSM Taurus is the latest member of the Somos® high-toughness material series. Parts made of this material are easy to clean and process. For end users and component manufacturers, its ability to withstand higher heat distortion temperatures broadens the application range of light curing technology.

-

UTR 3000

UTR 3000

UTR 3000 is a high-precision photosensitive resin material with excellent dimensional accuracy, smooth surface and excellent detail performance.

-

UTR Therm

UTR Therm

UTR-Therm 1 photosensitive resin can withstand temperature up to 130℃, which can simulate the thermal performance of engineering plastics.

-

Somos ® EvoLVe 128

Somos ® EvoLVe 128

Somos® EvoLVe 128 is a low-viscosity photosensitive resin material developed by DSM.

-

UTR Flex

UTR Flex

UTR Flex is a high-precision photosensitive resin material with excellent flexible property, smooth surface and excellent detail performance.

-

Somos ® PerFORM

Somos ® PerFORM

Somos® PerFORM is a strong-performance, very hard, and high temperature-resistant composite material developed by DSM.

-

TDS EvoDent

TDS EvoDent

EvoDent Model V2.0 is a model material specially developed for dentistry.

-

Formlabs ESD Resin

Formlabs ESD Resin

A rugged ESD-safe material to improve your electronics manufacturing workflows.

-

PA12

PA12

Material type: Plastic, High strength, Impact resistant Nylon PA12 is the most common 3D printing material.

-

HP-PA-12

HP-PA-12

HP-PA has a variety of material properties that can meet the requirements of different scenarios.

-

Glass fiber nylon(PA12+35% GF)

Glass fiber nylon(PA12+35% GF)

Glass fiber nylon is PA12 nylon mixed with 35% glass fiber.

-

PLA

PLA

PLA (FDM) is used for low-cost, non-functional prototyping. Offers greater detail than ABS, but is more brittle. Unsuitable for high temperature applications.

-

PLA-CF

PLA-CF

PLA-CF is a composite reinforcement material made by mixing carbon fiber powder into a traditional polylactic acid (PLA) plastic matrix.

-

ABS

ABS

ABS is a common thermoplastic with good mechanical properties and excellent impact strength, superior to PLA but with less defined details.

-

Stratasys ABS-ESD7

Stratasys ABS-ESD7

ABS-ESD7™ (acrylonitrile butadiene styrene-electrostatic dissipative) is an ABS thermoplastic with static dissipative properties for applications where a static charge can damage products,

-

PETG

PETG

PTEG is a very tough, durable and easy to use material.

-

PETG-CF

PETG-CF

PETG-CF, short for carbon fiber reinforced polyethylene terephthalate-copolyester.

-

TPU(FDM)

TPU(FDM)

TPU is called thermoplastic polyurethane elastomer rubber. It is a type of polymer material between rubber and plastic.

-

TPU

TPU

TPU has excellent characteristics of high tension, high tensile force, toughness and aging resistance.

-

PC (Polycarbonate)

PC (Polycarbonate)

PC offers accuracy, durability and stability, creating strong parts that withstand functional testing.

-

ASA

ASA

ASA is a production-grade thermoplastic that can be combined with FDM technology to achieve perfect performance.

-

PEEK

PEEK

PEEK is an engineering thermoplastic with excellent mechanical and thermal properties.

-

PPS-CF

PPS-CF

PPS-CF is a carbon fiber reinforced polyphenylene sulfide composite.

-

Aluminum (AlSi10Mg)

Aluminum (AlSi10Mg)

Aluminum AlSi10Mg is an aluminum alloy that combines good strength and thermal properties with low weight and flexible post-processing possibilities.

-

Stainless steel 316L

Stainless steel 316L

Stainless steel is resistant to weak corrosive media such as air, steam, and water, and chemically corrosive media such as acid, alkali, and salt.

-

Titanium TC4

Titanium TC4

Titanium TC4 has good comprehensive mechanical properties, high specific strength (strength-weight ratio), low thermal conductivity, and excellent corrosion resistance, toughness and weldability.

-

Tool steel

Tool steel

Mold steel can maintain a certain strength even at high temperatures. In the process of injection molding, it is traditionally used in the manufacture of tools and abrasives in the process of injection molding and die casting.

-

Aluminum 5052

Aluminum 5052

5052 is an aluminium alloy, primarily alloyed with magnesium and chromium.

-

Aluminum 6061

Aluminum 6061

6061 is an alloy that is suitable for hot forging. The billet is heated through an induction furnace and forged using a closed die process.

-

Stainless steel 304

Stainless steel 304

Stainless Type 304 is one of the most versatile and commonly used grades of stainless steel.

-

Stainless Steel 316/316L

Stainless Steel 316/316L

Stainless Type 316 is a standard molybdenum-bearing austenitic stainless steel grade.

-

Stainless steel 201

Stainless steel 201

Stainless steel 201, with certain acid and alkali resistance, high density, no bubbles, no pinholes, etc.

-

Stainless Steel 301

Stainless Steel 301

Type 301 is an austenitic stainless steel with a nominal composition of 17 percent chromium and 7 percent nickel, which provides good strength and ductility when cold worked.

-

Mild steel 1018

Mild steel 1018

Mild steel 1018 is a widely used alloy with good machinability, weldability, toughness, strength, but it’s susceptible to corrosion on the surface.

-

Copper C110

Copper C110

Copper C110, being a tough pitch copper alloy, is not easily welded or brazed because it suffers from embrittlelment when heated in a reducing atmosphere.

-

Copper 260 (Brass)

Copper 260 (Brass)

C260 brass is the most ductile of the brasses and is used in greater quantity than any other copper-zinc alloy.

-

Copper 101

Copper 101

Copper alloy C101 is also known as HC or high conductivity copper.

-

PMMA (Acrylic)

PMMA (Acrylic)

Polymethyl methacrylate(PMMA), is a kind of high molecular polymer, also known as acrylic or plexiglass.

-

Carbon Fiber Plate

Carbon Fiber Plate

Carbon fiber plate is a board made of carbon fiber prepreg, which can replace the use of steel and aluminum.

-

ABS

ABS

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer and is an ideal choice for applications that require an inexpensive, strong, stiff plastic that holds up well to external impacts.

-

POM

POM

POM is a plastic material featuring a very high tensile strength, with an outstanding resistance to creep, allowing it to bridge the gaps of material properties between most of the plastics and metals.

-

Nylon

Nylon

Nylon plastic (PA) is a synthetic thermoplastic polymer commonly used in injection molding applications.

-

Polycarbonate (PC)

Polycarbonate (PC)

Polycarbonates (PC) is an amorphous thermoplastic.

-

PC/ABS

PC/ABS

PC/ABS is a thermoplastic made of PC and ABS alloys, which combines the excellent properties of both materials.

-

PVC

PVC

PVC plastic is budget-friendly, resistant to environmental degradation, chemicals, and alkalis, and has excellent tensile strength and hardness.

-

Polyethylene (PE)

Polyethylene (PE)

Polyethylene is a thermoplastic polymer with a variable crystalline structure and a vast range of applications depending on the particular type.

-

Polypropylene (PP)

Polypropylene (PP)

Polypropylene(PP) injection molding material , is a thermoplastic addition polymer made by combining several propylene monomers.

-

Polystyrene (PS)

Polystyrene (PS)

Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material.

-

TPU

TPU

TPUs are tough, durable, easy to clean and well-suited to applications that demand the elasticity of rubber combined with high stability.

-

ABS

ABS

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer and is an ideal choice for applications that require an inexpensive, strong, stiff plastic that holds up well to external impacts.

-

POM

POM

POM is a plastic material featuring a very high tensile strength, with an outstanding resistance to creep, allowing it to bridge the gaps of material properties between most of the plastics and metals.

-

Nylon

Nylon

Nylon is exceptionally strong, relatively resistant to abrasion and moisture absorptivity, long-lasting, resistant to chemicals, elastic, and easy to wash.

-

Polycarbonate (PC)

Polycarbonate (PC)

Polycarbonates (PC) is an amorphous thermoplastic.

-

PVC

PVC

PVC plastic is budget-friendly, resistant to environmental degradation, chemicals, and alkalis, and has excellent tensile strength and hardness.

-

Polyethylene (PE)

Polyethylene (PE)

Polyethylene is a thermoplastic polymer with a variable crystalline structure and a vast range of applications depending on the particular type.

-

Polypropylene (PP)

Polypropylene (PP)

Polypropylene(PP) injection molding material , is a thermoplastic addition polymer made by combining several propylene monomers.

-

Polystyrene (PS)

Polystyrene (PS)

Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material.

-

TPU

TPU

TPUs are tough, durable, easy to clean and well-suited to applications that demand the elasticity of rubber combined with high stability.

-

Rubber

Rubber

Silicone rubber is the material of choice in manufacturing rubber parts.

- Silver white

- Silver white

- Silver white

- Silver white

- Silver

- Silver

- Silver

- Silver

- Silver

- Brass

- Copper

- Silver

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Light Beige

- Black

- Light Beige

- Black

- Transparent to bluish-purple (increasing thickness)

- White

- Black

- Ivory

- Black

- Black

- White

- White

- Black

- White

- Black

- White

- Black

- Transparent

- Black

- White

- Pale brown

- Chrome yellow

- Green

- Yellow

- Black

- Black

- Black

- Matte white

- Black(paint)

- Transparent(Spray varnish)

- Matte diffuse

- Black (waxed)

- Translucent

- White

- Tender green

- Black(paint)

- Brown

- Red translucent

- White

- White

- Black

- Nano-Ceramic White

- Waxy yellow

- Black

- White

- Dark black (dyeing)

- Dark black (spray paint)

- Light gray

- Dark black (dyeing)

- White

- Black

- Grey

- Yellow

- Red

- Green

- Blue

- Orange

- Pink

- Multi-colors

- Marble

- Silk gold

- Silk silver

- Silk copper

- Arctic Whisper (blue-white gradient)

- Solar Breeze (red-white gradient)

- Ocean to Meadow (blue-green gradient)

- Black

- Royal blue

- Burgundy red

- Matcha green

- Lava gray

- Jeans blue

- Iris purple

- White

- Black

- Silver gray

- Red

- Blue

- Yellow

- Green

- Black

- White

- Black

- Grey

- Red

- Blue

- Yellow

- Green

- Black

- Violet Purple

- Titan Gray

- Brick Red

- Malachite Green

- Indigo blue

- White

- Black

- Red

- Yellow

- Blue

- Gray

- Green

- White

- Black

- white

- Black

- translucent

- Black translucent

- White

- Black

- Grey

- Red

- Blue

- Green

- Pale brown

- Black

- Metallic

- Metallic

- Metallic

- Metallic

- Silver white

- Silver white

- Silver

- Silver

- Silver

- Silver

- Silver gray

- Copper

- Brass

- Copper

- Transparent

- Black

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- DLP

- SLA

- DLP

- SLA

- SLS

- MJF

- SLS

- FDM

- FDM

- FDM

- FDM

- FDM

- FDM

- FDM

- SLS

- FDM

- FDM

- FDM

- FDM

- SLM

- SLM

- SLM

- SLM

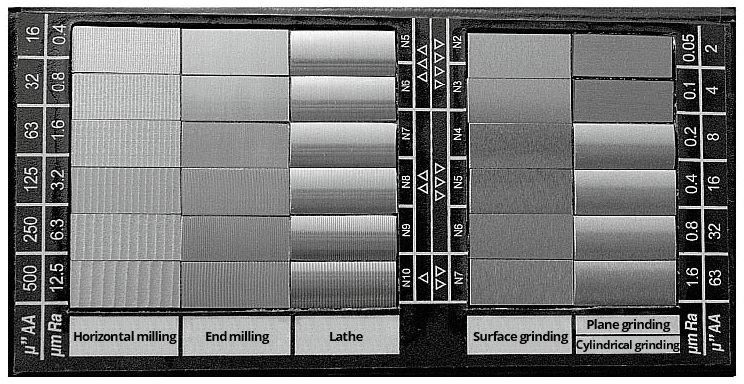

Support surface

Support surface

- SPI B-3

- SPI A-1

- SPI A-2

- SPI A-3

- SPI B-1

- SPI B-2

- SPI C-1

- SPI C-2

- SPI C-3

- SPI D-1

- SPI D-2

- SPI D-3

- e.g.

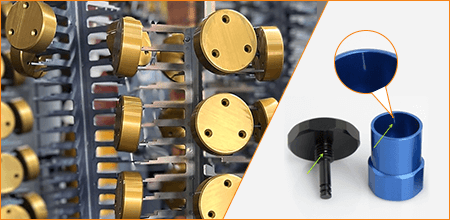

We will keep the mold for 2 years. You can continue to order parts until the end of the life of the mold. After the mold expires, it will be recycled by default. If you need to send the mold to you, please contact the sales rep about shipment.

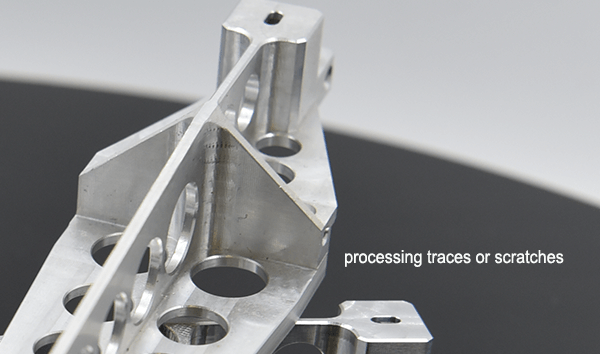

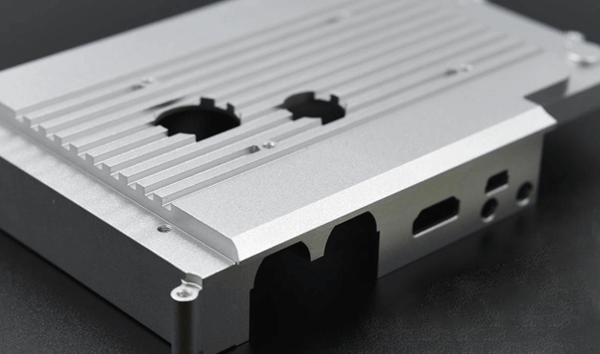

Discrepancy warning

Discrepancy warning

Due to the particularity and scarcity of the surface finish process, different batches of orders cannot be guaranteed to have the same finish. For example: Aluminum anodized color, there will be color difference more or less with each time, even though you choose the same opition of color.

If you need the totally same surface finish of batch products and samples, it is recommended to keep 1-2 samples at 3PCB, and then we can mass-produce the specified products according to the samples.

you can also add 0 surface treatments

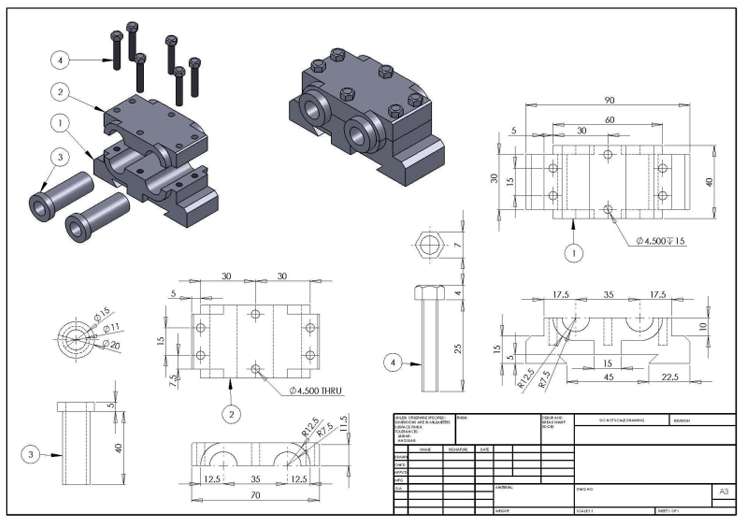

Tapped Holes:

- No extra fee

- 3PCB will do the dimension and surface feature inspections based on the drawings provided by the customer.

- Pay extra

- 2D technical drawings are required.

- Pay extra

- 2D technical drawings are required.

- Pay extra

- 2D technical drawings are required.

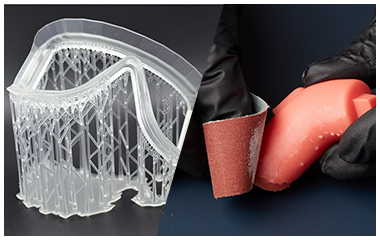

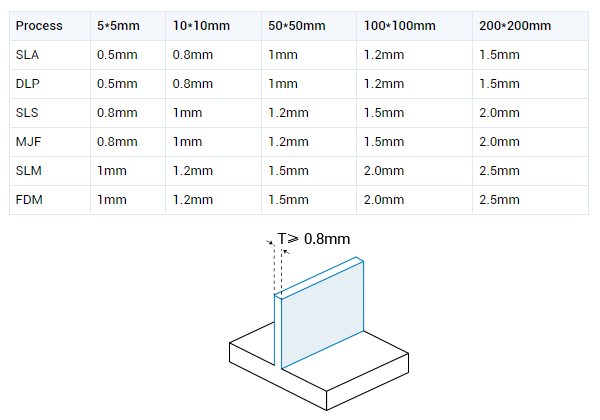

The wall thickness standard:

The wall thickness directly determines the strength of the printed object, and also determines whether the model can be printed. Once the model is printed, it also goes through support removal, grinding and sandblasting, which determine the minimum wall thickness for different materials. The model is printable only when the wall thickness meets the minimum requirement.

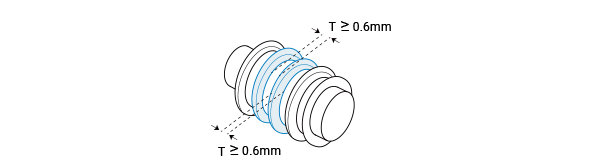

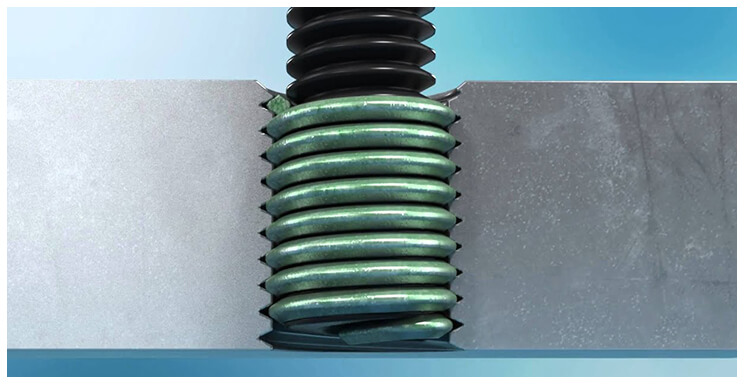

The thread printing standard:

Pitch refers to the axial distance between the corresponding points of two adjacent teeth on the thread. Profile angle refers to the angle between the two sides of the whorl profile. Your design needs to meet the requirements of minimum pitch:0.6mm and minimum profile angle:20°