End-to-End PCB Assembly Solutions

From early prototypes to volume builds, 3PCB delivers reliable PCB assembly with the flexibility engineers need and the consistency production demands.

Assembly Capabilities Overview

3PCB supports a wide range of assembly configurations to match real-world design requirements:

- Surface-mount component assembly

- Through-hole component insertion

- Hybrid SMT + THT builds

- Single-side and double-side population

- Automated lines with skilled manual support when needed

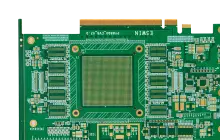

Integrated PCB Fabrication

We produce assembly-ready PCBs with advanced stack-ups, fine trace control, and stable quality from prototype to production.

Order Now

Complete PCBA Services

From design to delivery, 3PCB handles everything-so you can focus on your product.

Order Now

Precision Stencil at No Extra Cost

Every qualified assembly order includes a high-accuracy solder paste stencil.

Order Now

One Partner for PCB Fabrication & Assembly

By combining PCB manufacturing and assembly under one roof, we reduce handling risks, shorten lead times, and simplify logistics. The result is a smoother experience and a more reliable finished product.

-

248700+Registered (includ CN)

-

9500+Successful Payment

-

96.8%On-time delivery rate

-

64800+Daily processed order

Complete PCB Manufacturing & Assembly Services

Our PCB manufacturing and assembly services cover the full production workflow-from file preparation and component packaging to soldering, inspection, and final testing. We support a wide range of component types, board sizes, and assembly technologies, including SMT, THT, and mixed assembly.

| Category | Specification |

|---|---|

| Assembly Types | SMT Assembly; THT Assembly; 2-Sided SMT & THT Assembly; Mixed Technology Assembly |

| Supported File Formats | Gerber RS-274X; BOM (.xls, .csv, .xlsx); Pick-and-Place / XY Files |

| Component Footprints | 0201, 0402, 0603, and above; BGA, QFN, QFP, PLCC; SOIC, POP; Connectors |

| Minimum Component Pitch | 8 mils |

| Component Packaging | Reel Packaging; Cut Tape Packaging; Tube & Tray; Loose Parts / Bulk |

| Soldering Processes | Reflow Soldering; Wave Soldering |

| Solder Types | Lead-Free (RoHS); Leaded Solder |

| Inspection & Testing | Visual Inspection; AOI (Automated Optical Inspection); ICT (In-Circuit Test); X-Ray Inspection |

| Reflow Profiles | Standard Reflow Profile; Custom Reflow Profile |

| Board Size Limits | Minimum Board Size: 0.2" × 0.2"; Maximum Board Size: 15" × 20" |

Advanced PCB Assembly & Integration

PCB Fabrication

High-Precision Board Manufacturing We manufacture PCBs according to the customer's design files and technical requirements, supporting advanced multilayer structures, fine-line processing, and impedance-controlled layouts to ensure electrical integrity and manufacturability.

Key Processes:

- Multilayer fabrication (up to 14 layers)

- Fine line/spacing and microvias

- HDI, blind/buried vias, via-in-pad

- Impedance control and custom stack-ups

- Special materials, finishes, and edge plating

- 100% electrical testing

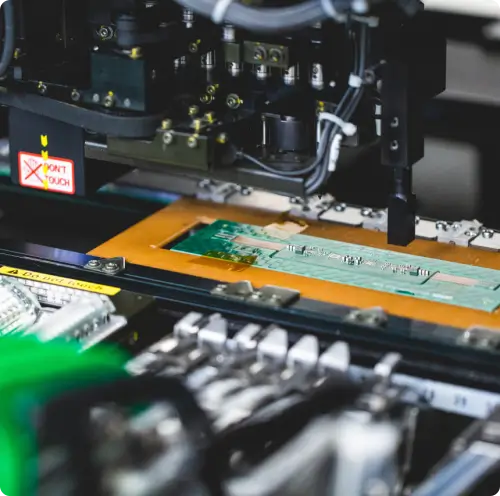

PCB Assembly

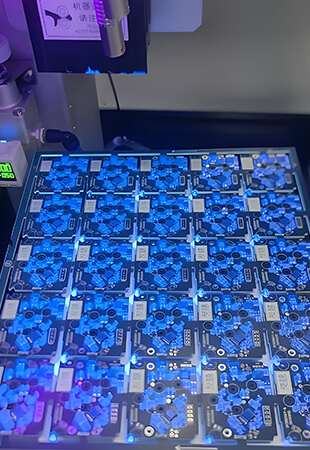

SMT, THT & Mixed-Technology Assembly Components are assembled using automated SMT lines and THT processes based on production volume and design complexity. Both lead-free and leaded soldering are supported, with controlled reflow profiles for quality consistency.

Key Processes:

- SMT, THT, and mixed assembly

- BGA, QFN, QFP, Micro-BGA, POP packages

- Reflow soldering & wave soldering

- AOI, X-ray, ICT inspection

- Custom reflow profiles and high-density assembly

Parts Management

Component Sourcing, Verification & Inventory Control All components are sourced, verified, and managed through a structured procurement and quality control system to ensure authenticity, availability, and cost efficiency.

Key Processes:

- Turnkey component sourcing

- Rare/EOL component procurement

- BOM analysis, cross-referencing & substitution

- Incoming inspection & electrical verification

- Inventory management and kitting

- 24-hour BOM pricing

Functional Testing

Electrical, Functional & Environmental Validation Each assembled board is tested according to customer-defined test plans to verify electrical performance, functional behavior, and environmental reliability.

Key Processes:

- AOI, X-ray, ICT, FCT

- Embedded system testing

- Custom test software

- Signal integrity, I/O, power validation

- High/low temperature & humidity testing

- Vibration, shock, and drop testing

IC Programming

Secure Device Programming & Data Verification ICs are programmed before or after assembly based on project requirements, with strict data security and verification to ensure firmware accuracy and IP protection.

Key Processes:

- Pre-assembly or in-circuit programming

- MCU, FPGA, Flash, EEPROM programming

- Multi-package support (QFN, BGA, CSP, etc.)

- Checksum verification & data validation

- Secure data handling & IP protection

Full Product Assembly

System Integration, Box Build & Final Delivery PCBAs are integrated into the final product, including mechanical assembly, wiring, enclosure installation, and functional verification for complete, ready-to-ship systems.

Key Processes:

- Electro-mechanical assembly

- Cable & wire harness integration

- Box-build and enclosure installation

- Functional prototypes and appearance models

- Customized QA plans

- Final inspection and packaging

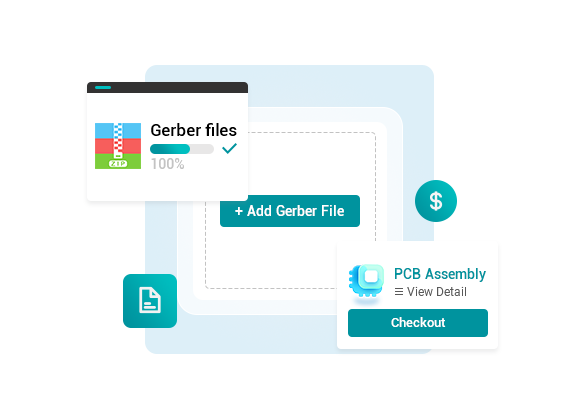

How Our Online PCB Assembly Works

Upload your Gerber files for PCB fabrication so we can produce bare boards to your specifications.

Submit your BOM and CPL / Pick-and-Place files to define components and placement.

Validate with our online system, which automatically reviews your files and flags potential issues before production.

Check with integrated DFM & DFA analysis to catch footprint mismatches, polarity risks, or spacing concerns early-saving time and cost.

Advanced PCB Assembly & Integration

Your Trusted PCB Assembly Partner

Whether you're validating a new design or preparing for production, our PCBA service helps you move forward with confidence.

Get instant quote

.jpg)

.jpg)