Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

Unit price would decreases as quantity increases. VAT and freight are excluded.

- ≤10,000pcs

- 10,000-50,000pcs

- 50,000-100,000pcs

- ≥100,000pcs

- mm

- inch

- cm

- Aluminum

- Stainless steel

- Brass

- Copper

- Titanium

- Mild steel

- Alloy steel

- Tool steel

- Spring steel

- ABS

- Polycarbonate (PC)

- Nylon

- Polypropylene (PP)

- POM

- PTFE (Teflon)

- PMMA (Acrylic)

- Polyethylene (PE)

- PEEK

- Bakelite

- FR4

- Rubber

- Carbon Fiber

- Resin

- Nylon

- PLA

- ABS

- PETG

- TPU

- PC

- ASA

- PEEK

- PPS

- Aluminum

- Stainless steel

- Titanium

- Tool steel

- Aluminum

- Stainless steel

- Mild steel

- Copper

- PMMA (Acrylic)

- Carbon Fiber

- ABS

- POM

- Nylon

- Polycarbonate (PC)

- PC/ABS

- PVC

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- TPU

- ABS

- POM

- Nylon

- Polycarbonate (PC)

- PVC

- Polyethylene (PE)

- Polypropylene (PP)

- Polystyrene (PS)

- TPU

- Rubber

Heat alert

Heat alert

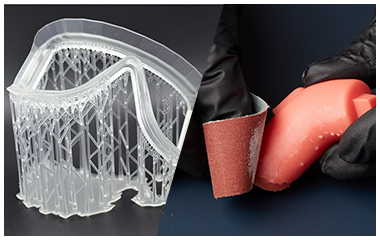

To prevent parts with easily deformable structures from deforming during transportation, as the gradual increase in weather temperature.

1. It's recommended to use the following Resin models with good heat resistant and strength: Somos® Ledo, Somos® Taurus, Somos® Perform, UTR 8220, UTR Flex, UTR Therm.

2. Wall thickness is thicken into ≥2mm.

Deformation warning (For non-metal parts with easily deformable structure)

Deformation warning (For non-metal parts with easily deformable structure)

Non-metal parts with easily deformable structure would occasionally deform when squeezed by external force during transportation.

1. For those who choose Resin materials, it's recommended to use the following Resin models with good heat resistant and strength: Somos®Ledo, Somos®Taurus, Somos®Perform, UTR 8220, UTR Flex, UTR Therm.

2.Wall thickness is thicken into ≥2mm.

3.Nylon is preferred over resin for parts with easily deformable structure.

4.Deformed parts can be corrected by heating process, like using hot air gun or hot water.

-

Aluminum 6061

Aluminum 6061

A precipitation-hardened, heat-treatable aluminum-magnesium-silicon alloy. The T6 temper indicates it has been solution heat treated and artificially aged to achieve its peak strength.

-

Aluminum 7075

Aluminum 7075

A high-strength, precipitation-hardened aluminum-zinc alloy. The T6 temper indicates it has been solution heat treated and artificially aged to achieve its peak strength.

-

Aluminum 5052

Aluminum 5052

A work-hardened, non-heat-treatable aluminum alloy with excellent corrosion resistance, especially in marine environments, good weldability, and moderate strength. The H32 temper indicates it has been strain hardened and then stabilized to a condition approximately midway between fully soft (O) and fully hard (H38).

-

Aluminum 2A12

Aluminum 2A12

A high-strength, heat-treatable aluminum-copper-magnesium alloy (Al-Cu-Mg system). The T4 temper indicates it has been solution heat treated, quenched, and then naturally aged to a substantially stable condition.

-

Stainless steel 304

Stainless steel 304

Stainless Steel 304, the most widely used and versatile grade. It offers an excellent combination of good corrosion resistance, formability, weldability, and toughness.

-

Stainless steel 316/316L

Stainless steel 316/316L

Stainless Steel 316/316L, a premium alloy derived from 304 with the key addition of 2-3% molybdenum. This addition provides significantly improved corrosion resistance, particularly against pitting and crevice corrosion in chloride environments (e.g., seawater, chemical process streams).

-

Stainless steel 303

Stainless steel 303

Stainless Steel 303, free-machining stainless steel, derived from SS304 with additions of sulfur (and sometimes selenium) to dramatically improve machinability.

-

Stainless steel 430

Stainless steel 430

Stainless Steel 430, straight-chromium (17%) stainless steel. It is magnetic, offers good corrosion resistance in mild atmospheres, and has excellent resistance to stress corrosion cracking. Its key advantages are lower cost than 300-series austenitics and better thermal conductivity.

-

Stainless steel 201

Stainless steel 201

Stainless Steel 201 is part of the chromium-nickel-manganese family. It is a lower-cost alternative to SS304, achieved by replacing some nickel with manganese and nitrogen. It is non-magnetic in the annealed condition (may become slightly magnetic after cold working/machining).

-

Brass C360

Brass C360

C360 is a leaded brass alloy (copper-zinc alloy with added lead) specifically engineered for superior machinability. It is widely regarded as the benchmark for machinability among all metals, often rated at 100% on comparative scales.

-

Copper

Copper

Copper C110, 99.9% pure copper alloy that is the most widely used general-purpose copper worldwide. It contains a small, controlled amount of oxygen (0.02-0.04%) which improves castability and reduces porosity, but this oxygen makes it unsuitable for high-temperature reducing atmospheres (risk of hydrogen embrittlement).

-

Titanium Gr5 (TC4)

Titanium Gr5 (TC4)

The most widely used and versatile titanium alloy, accounting for over 50% of all titanium usage. It is an alpha-beta alloy containing 6% aluminum and 4% vanadium, offering an excellent combination of high strength-to-weight ratio, good fatigue resistance, and moderate corrosion resistance.

-

Mild steel 1018

Mild steel 1018

A general-purpose, low-carbon, non-hardenable plain carbon steel and one of the most widely available and commonly machined ferrous materials. It offers a good balance of strength, ductility, and excellent machinability, especially in its cold-drawn ("bright") condition.

-

Mild steel 1045

Mild steel 1045

A versatile medium-carbon, heat-treatable plain carbon steel offering a significant increase in strength and wear resistance over 1018, while maintaining good machinability. With approximately 0.45% carbon, it can be through-hardened by quenching and tempering to achieve a wide range of strength and toughness combinations.

-

Mild steel A36

Mild steel A36

A low-carbon, general-purpose structural steel defined by the ASTM A36 standard. It is the most common steel used in construction and fabrication in the United States.

-

Alloy steel 4140

Alloy steel 4140

A versatile, medium-carbon, low-alloy steel containing chromium and molybdenum. It is renowned for its high strength, good toughness, and excellent fatigue resistance.

-

Alloy steel 4340

Alloy steel 4340

A high-strength, low-alloy steel containing nickel, chromium, and molybdenum. It is renowned for its exceptional combination of high strength, toughness, and good fatigue resistance, achievable through proper heat treatment.

-

Alloy steel 1215

Alloy steel 1215

A low-carbon, rephosphorized/resulfurized free-machining steel. It is engineered specifically for high-speed, high-volume CNC machining, particularly on automatic screw machines (Swiss-type lathes) and CNC lathes/mills.

-

Tool steel D2

Tool steel D2

The industry benchmark for high-wear-resistance, air-hardening cold work tool steel. It contains a very high volume of large, hard chromium carbides, giving it exceptional abrasion resistance—second only to powder metallurgy (PM) steels and carbides among common toolroom materials.

-

Tool steel A2

Tool steel A2

A versatile, air-hardening, medium-alloy tool steel known for its excellent balance of wear resistance, toughness, and dimensional stability during heat treatment. It contains chromium for hardenability and wear resistance, and molybdenum and vanadium for grain refinement and toughness.

-

Tool steel O1

Tool steel O1

A classic, manganese-chromium-tungsten oil-hardening cold work tool steel. It is renowned for its good machinability in the annealed state, excellent dimensional stability during oil quenching (low distortion), and its ability to achieve a very hard, fine-grained microstructure.

-

Tool steel A3

Tool steel A3

An air-hardening, high-carbon, high-chromium cold work tool steel that offers very high wear resistance, second only to the D-series (e.g., D2) among common tool steels, while maintaining a good degree of toughness.

-

Tool steel S7

Tool steel S7

A silicon-chromium alloyed, air-hardening tool steel specifically engineered for exceptional impact toughness and shock resistance, combined with good wear resistance. It is part of the "S-grade" shock-resistant steels.

-

Tool steel H13

Tool steel H13

A versatile, chromium-based hot work tool steel renowned for its excellent combination of hot hardness, thermal fatigue resistance (resistance to heat checking), and good toughness.

-

Spring steel

Spring steel

Spring Steel 1065, a high-carbon, non-alloy steel known for its ability to be heat treated to achieve high strength, hardness, and excellent elastic properties (springiness). In its annealed or spheroidized condition, it is supplied soft for machining and forming.

-

ABS

ABS

ABS is an amorphous thermoplastic terpolymer widely used for CNC machining due to its excellent combination of strength, rigidity, impact resistance, and ease of processing. In sheet, rod, and tube stock form, it offers isotropic properties, predictable behavior, and outstanding surface finish after machining.

-

ABS Flame Retardant

ABS-Flame-Retardant

Flame Retardant ABS is an Acrylonitrile Butadiene Styrene thermoplastic compounded with additives (typically brominated or phosphorous-based compounds, often synergized with antimony trioxide) to inhibit or suppress combustion.

-

Polycarbonate (PC)

Polycarbonate (PC)

Polycarbonate is a high-performance, amorphous engineering thermoplastic renowned for its exceptional impact strength (the highest among clear plastics), high heat resistance, and excellent dimensional stability.

-

Nylon 6

Nylon 6

Nylon 6 (PA6) is a tough, semi-crystalline engineering thermoplastic widely used for CNC machining. It offers an excellent balance of mechanical strength, wear resistance, chemical resistance, and self-lubricating properties.

-

Nylon 12

Nylon 12

Nylon 12 (PA12) is a high-performance, long-chain semi-crystalline thermoplastic from the nylon family. It is distinguished from PA6 and PA66 by its significantly lower moisture absorption, superior dimensional stability, lower density, and excellent impact resistance at low temperatures.

-

Polypropylene (PP)

Polypropylene (PP)

Polypropylene is a versatile, semi-crystalline thermoplastic known for its excellent chemical resistance, low density, good fatigue resistance, and low cost.

-

POM

POM

POM is a high-performance, semi-crystalline engineering thermoplastic prized in CNC machining for its exceptional dimensional stability, high stiffness and strength, excellent creep resistance, and natural lubricity (low friction).

-

Teflon

Teflon

PTFE is a fully fluorinated, semi-crystalline, high-performance fluoropolymer. It is renowned for its extreme chemical inertness, the lowest coefficient of friction of any solid material, excellent high and low-temperature performance, and outstanding dielectric properties.

-

PMMA

PMMA

A transparent, amorphous thermoplastic polymer renowned for its exceptional optical clarity, good weather resistance, and rigidity. It is significantly stronger and more scratch-resistant than polycarbonate (PC) but is more brittle and has lower impact strength.

-

Polyethylene (PE)

Polyethylene (PE)

HDPE is a semi-crystalline thermoplastic from the polyethylene family, characterized by its high strength-to-density ratio, excellent chemical resistance, and low moisture absorption.

-

PEEK

PEEK

PEEK is a high-performance semi-crystalline thermoplastic from the polyaryletherketone (PAEK) family. It is an engineering polymer renowned for its exceptional combination of properties: high mechanical strength and stiffness maintained at elevated temperatures, outstanding chemical and wear resistance, excellent fatigue performance, and inherent flame retardancy.

-

Bakelite

Bakelite

The original synthetic plastic, a thermoset polymer created by cross-linking phenol and formaldehyde under heat and pressure, often reinforced with paper, canvas (linen), or wood flour fillers.

-

FR4

FR4

FR-4 is not a pure polymer but a composite laminate consisting of continuous woven fiberglass cloth impregnated with an epoxy resin matrix, cured under heat and pressure. It is designated as a Flame Retardant (FR) material, typically meeting UL94 V-0 standard.

-

Rubber

Rubber

It covers the CNC machining of solid, non-cellular (non-foam) elastomeric materials. Unlike thermoplastics, these are often thermoset or highly cross-linked materials, characterized by high elasticity, low durometer (softness), and high damping.

-

Carbon Fiber Plate

Carbon Fiber Plate

A high-performance composite material consisting of continuous carbon fibers embedded in a thermosetting polymer matrix (typically epoxy).

-

Standard white material (UTR 8360)

Standard white material (UTR 8360)

It is engineered to provide exceptional mechanical properties, including very high stiffness, strength, and dimensional stability, approaching or exceeding those of some engineering thermoplastics.

-

UTR Imagine Black

UTR Imagine Black

Its primary purpose is to produce aesthetic prototypes, high-contrast visual models, and presentation-quality parts with an opaque, deep matte or semi-gloss black finish that hides layer lines exceptionally well.

-

UTR-8100 (transparent)

UTR-8100 (transparent, Spray varnish)

It is formulated to produce parts with exceptional optical transparency, high dimensional accuracy, and good mechanical properties.

-

PWR Dark Black

PWR Dark Black

It is designed to simulate the mechanical feel and performance of ABS plastic, offering a good balance of strength, toughness, and thermal resistance at a competitive cost.

-

UTR-8100 (translucent)

UTR-8100 (translucent)

It offers a balance of good mechanical properties, dimensional accuracy, and a naturally translucent off-white/cream appearance.

-

Somos ® Ledo

Somos ® Ledo

It is optimized for fast print speeds and easy support removal while producing parts with a smooth, matte surface finish.

-

UTR 8220

UTR 8220

It is specifically formulated to bridge the gap between rigid prototyping resins and flexible elastomers, offering an exceptional combination of toughness, high elongation, and impact resistance while maintaining usable rigidity.

-

Somos ® Taurus

Somos ® Taurus

It is engineered to produce parts that maintain structural integrity and dimensional stability at elevated temperatures, making it suitable for demanding thermal environments.

-

UTR 3000

UTR 3000

It is engineered to simulate the mechanical behavior of engineering thermoplastics like ABS or polycarbonate blends, offering an outstanding combination of impact resistance, toughness, and good elongation at break.

-

UTR Therm

UTR Therm

The UTR-Therm series (e.g., UTR-Therm 120, UTR-Therm 180) is engineered to produce parts with elevated Heat Deflection Temperatures (HDT), high rigidity, and excellent dimensional stability.

-

Somos ® EvoLVe 128

Somos ® EvoLVe 128

It is formulated to produce parts that mimic the clarity, toughness, and durability of engineered thermoplastics like polycarbonate (PC).

-

UTR Flex

UTR Flex

It is formulated to produce parts that mimic the properties of soft rubber or silicone, characterized by low durometer (Shore A scale),

-

Somos ® PerFORM

Somos ® PerFORM

It is filled with ceramic or mineral particles, which grant it exceptionally high heat deflection temperature (HDT), rigidity, and dimensional stability far exceeding standard prototyping resins.

-

TDS EvoDent

TDS EvoDent

A biocompatible, CE-marked (Class IIa), and FDA-listed photopolymer resin specifically formulated for the additive manufacturing of definitive dental surgical guides, splints, and other short-term (<30 days) mucosal or bone-contact devices.

-

Formlabs ESD Resin

Formlabs ESD Resin

Its primary function is to provide permanent and consistent electrostatic discharge (ESD) protection, with a surface resistance in the range of 10^6 to 10^9 ohms.

-

PA12

PA12

The industry-standard polyamide 12 (Nylon 12) powder specifically engineered for the Selective Laser Sintering (SLS) additive manufacturing process.

-

HP-PA-12

HP-PA-12

A fine polyamide 12 (Nylon 12) powder engineered specifically for the HP Multi Jet Fusion (MJF) additive manufacturing process. This is the flagship and most widely used material for industrial MJF printing.

-

Glass fiber nylon(PA12+35% GF)

Glass fiber nylon(PA12+35% GF)

A high-performance composite material consisting of polyamide 12 (Nylon 12) reinforced with 35% by weight of short glass fibers.

-

PLA

PLA

A proprietary, enhanced Polylactic Acid (PLA) composite filament developed by Bamboo Lab for their line of Fused Deposition Modeling (FDM) 3D printers.

-

PLA-CF

PLA-CF

A composite filament consisting of Polylactic Acid (PLA) infused with short carbon fiber strands.

-

ABS

ABS

BS is a classic engineering thermoplastic known for its good toughness, impact resistance, and moderate heat resistance.

-

Stratasys ABS-ESD7

Stratasys ABS-ESD7

It is based on ABS (Acrylonitrile Butadiene Styrene) but is compounded with permanent carbon-based additives to provide a consistent, bulk-volume resistivity in the range of 10^6 to 10^9 ohm-cm.

-

PETG

PETG

PETG is a popular "bridge" material that combines the ease of printing of PLA with improved toughness, chemical resistance, and temperature resistance of ABS, while largely eliminating ABS's warping and fume issues.

-

PETG-CF

PETG-CF

Engineered for Bamboo Lab's Fused Deposition Modeling (FDM) printers, this material aims to enhance the base PETG with increased stiffness (modulus), improved dimensional stability, and reduced warping, while adding the distinctive carbon fiber aesthetic.

-

TPU(FDM)

TPU(FDM)

TPU is a class of elastic, rubber-like thermoplastics known for their high flexibility, elasticity, abrasion resistance, and toughness.

-

TPU

TPU

SLS TPU produces parts that are inherently flexible, elastic, and durable, simulating the properties of molded rubber or elastomers.

-

PC (Polycarbonate)

PC (Polycarbonate)

PC is renowned for its exceptional impact strength, high heat resistance, and good optical clarity (in its pure form).

-

ASA

ASA

ASA is often considered the outdoor-grade successor to ABS, replacing the butadiene rubber in ABS with an acrylate elastomer.

-

PEEK

PEEK

It represents the pinnacle of performance for polymer additive manufacturing, offering an exceptional combination of properties: extremely high continuous service temperature, outstanding chemical resistance, superb mechanical strength and stiffness retained at elevated temperatures, excellent wear and fatigue resistance, and inherent flame retardancy.

-

PPS-CF

PPS-CF

This material combines the inherent chemical resistance, dimensional stability, and thermal performance of PPS with the enhanced stiffness, strength, and reduced warp provided by carbon fiber (CF) reinforcement.

-

Aluminum (AlSi10Mg)

Aluminum (AlSi10Mg)

It offers an excellent combination of good strength, high hardness, good thermal properties, and low density, making it ideal for lightweight, complex geometries.

-

Stainless steel 316L

Stainless steel 316L

It is characterized by its exceptional corrosion resistance, good mechanical properties, excellent biocompatibility, and high ductility.

-

Titanium TC4

Titanium TC4

It offers an exceptional strength-to-weight ratio, outstanding corrosion resistance, excellent biocompatibility, and high fatigue strength.

-

Tool steel

Tool steel

It is characterized by an exceptional combination of high hardness (attained after heat treatment), excellent toughness, good thermal fatigue resistance (resistance to heat checking), and moderate wear resistance.

-

Aluminum 5052

Aluminum 5052

It is one of the most common and versatile general-purpose aluminum sheet alloys for fabrication.

-

Aluminum 6061

Aluminum 6061

It is the most widely used and versatile structural aluminum alloy, offering an excellent combination of medium-to-high strength, good toughness, and very good corrosion resistance.

-

Stainless steel 304

Stainless steel 304

The most common and versatile austenitic stainless steel. It is the benchmark material for sheet metal fabrication, offering an excellent combination of corrosion resistance, formability, weldability, and ease of cleaning.

-

Stainless Steel 316/316L

Stainless Steel 316/316L

A molybdenum-bearing, low-carbon austenitic stainless steel and the premium standard for enhanced corrosion resistance. The addition of 2-3% Molybdenum (Mo) dramatically improves its resistance to pitting and crevice corrosion, particularly in chloride environments.

-

Stainless steel 201

Stainless steel 201

An austenitic, low-nickel, work-hardening stainless steel. It is a cost-effective substitute for SS 304/304L in many applications, offering good corrosion resistance, high strength, and excellent formability in its annealed state.

-

Stainless Steel 301

Stainless Steel 301

A chromium-nickel austenitic stainless steel specifically engineered for high strength achieved through cold working. It has a lower nickel and higher chromium content than SS 304, resulting in a metastable austenitic structure.

-

Mild steel 1018

Mild steel 1018

A general-purpose, low-carbon, non-alloy steel and the most common and economical "mild steel" used in sheet metal fabrication.

-

Copper C110

Copper C110

The standard, commercially pure copper (minimum 99.9% Cu) and the most widely used copper alloy in general fabrication and electrical applications.

-

Copper 260 (Brass)

Copper 260 (Brass)

A high-leaded, alpha-beta brass (Cu-Zn-Pb alloy) and the industry standard for "free-machining" brass.

-

Copper 101

Copper 101

This "oxygen-free" quality gives it superior ductility, electrical and thermal conductivity, and resistance to hydrogen embrittlement (a failure mode in high-temperature, reducing atmospheres).

-

PMMA (Acrylic)

PMMA (Acrylic)

A transparent, amorphous thermoplastic polymer renowned for its exceptional optical clarity, good weather resistance, and rigidity.

-

Carbon Fiber Plate

Carbon Fiber Plate

A high-performance composite material consisting of continuous carbon fibers embedded in a thermosetting polymer matrix (typically epoxy).

-

ABS

ABS

ABS is a versatile, impact-resistant, and rigid thermoplastic produced by polymerizing styrene and acrylonitrile in the presence of polybutadiene.

-

POM

POM

POM is a highly crystalline, rigid, and strong engineering thermoplastic renowned for its exceptional dimensional stability, low friction, high stiffness, and excellent fatigue endurance.

-

Nylon

Nylon

Known for their outstanding mechanical properties, wear resistance, and chemical resistance, nylons are versatile engineering plastics.

-

Polycarbonate (PC)

Polycarbonate (PC)

Polycarbonate is a transparent, rigid, and exceptionally tough engineering thermoplastic characterized by its outstanding impact strength, high heat resistance, and excellent dimensional stability.

-

PC/ABS

PC/ABS

ABS/PC is an engineering polymer alloy that combines the heat resistance, impact strength, and rigidity of Polycarbonate (PC) with the processability, cost-effectiveness, and surface finish of ABS.

-

PVC

PVC

It is inherently flame retardant, chemically resistant, and cost-effective.

-

Polyethylene (PE)

Polyethylene (PE)

Polyethylene is the most widely produced plastic in the world, known for its excellent chemical resistance, low cost, good impact strength, and ease of processing.

-

Polypropylene (PP)

Polypropylene (PP)

It is characterized by its excellent chemical resistance, low density, good fatigue resistance, and outstanding electrical insulating properties.

-

Polystyrene (PS)

Polystyrene (PS)

PS is characterized by its excellent dimensional stability, ease of processing, and good optical clarity in its unmodified form.

-

TPU

TPU

TPU is a versatile class of elastomers that combines the elastic, rubber-like properties of vulcanized rubber with the melt-processability of thermoplastics.

-

ABS

ABS

It offers an excellent, balanced combination of good mechanical strength, impact resistance, dimensional stability, and ease of processing.

-

POM

POM

A semi-crystalline, high-performance engineering thermoplastic known for its high stiffness, excellent dimensional stability, low friction/wear properties, and good chemical resistance.

-

Nylon

Nylon

Vacuum-cast "nylon-like" parts are ideal for functional prototypes that require high durability, impact resistance, and performance under mechanical stress, especially where flexibility and toughness are more critical than extreme stiffness.

-

Polycarbonate (PC)

Polycarbonate (PC)

Vacuum-cast "PC-like" parts are essential for prototypes requiring high durability, optical clarity (when specified), and performance in demanding mechanical or thermal environments.

-

PVC

PVC

Vacuum-cast "PVC-like" parts are used for prototypes requiring soft-touch surfaces, seals, gaskets, tubes, and flexible components that simulate the feel and function of production vinyl or plastisol parts.

-

Polyethylene (PE)

Polyethylene (PE)

Vacuum-cast "PE-like" parts are used for prototypes of containers, fluid handling components, low-wear parts, and flexible packaging models where chemical inertness or specific tactile properties are needed.

-

Polypropylene (PP)

Polypropylene (PP)

Vacuum-cast "PP-like" parts are ideal for prototypes of containers, living hinges, automotive interiors, and laboratory/medical components where a specific combination of chemical resistance, light weight, and flexibility is required.

-

Polystyrene (PS)

Polystyrene (PS)

Vacuum-cast "PS-like" parts are primarily used for optical models, display prototypes, and rigid, dimensionally stable models where transparency and form accuracy are prioritized over impact resistance.

-

TPU

TPU

Vacuum-cast TPU is the premier material for prototyping flexible, durable, and resilient components that require a robust rubber-like performance.

-

Rubber

Rubber

These materials are poured as liquids into silicone moulds and cure to form solid parts with a wide range of softness (Shore OO to Shore A 80), high elongation, and excellent elastic recovery.

- Silver white

- Silver white

- Silver white

- Silver white

- Silver

- Silver

- Silver

- Silver

- Silver

- Brass

- Copper

- Silver

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Silver gray

- Light Beige

- Black

- Light Beige

- Black

- Transparent to bluish-purple (increasing thickness)

- White

- Black

- Ivory

- Black

- Black

- White

- White

- Black

- White

- Black

- White

- Black

- Transparent

- Black

- White

- Pale brown

- Chrome yellow

- Green

- Yellow

- Black

- Black

- Black

- Matte white

- Black(paint)

- Transparent(Spray varnish)

- Matte diffuse

- Black (waxed)

- Translucent

- White

- Tender green

- Black(paint)

- Brown

- Red translucent

- White

- White

- Black

- Nano-Ceramic White

- Waxy yellow

- Black

- White

- Dark black (dyeing)

- Dark black (spray paint)

- Light gray

- Dark black (dyeing)

- White

- Black

- Grey

- Yellow

- Red

- Green

- Blue

- Orange

- Pink

- Multi-colors

- Marble

- Silk gold

- Silk silver

- Silk copper

- Arctic Whisper (blue-white gradient)

- Solar Breeze (red-white gradient)

- Ocean to Meadow (blue-green gradient)

- Black

- Royal blue

- Burgundy red

- Matcha green

- Lava gray

- Jeans blue

- Iris purple

- White

- Black

- Silver gray

- Red

- Blue

- Yellow

- Green

- Black

- White

- Black

- Grey

- Red

- Blue

- Yellow

- Green

- Black

- Violet Purple

- Titan Gray

- Brick Red

- Malachite Green

- Indigo blue

- White

- Black

- Red

- Yellow

- Blue

- Gray

- Green

- White

- Black

- white

- Black

- translucent

- Black translucent

- White

- Black

- Grey

- Red

- Blue

- Green

- Pale brown

- Black

- Metallic

- Metallic

- Metallic

- Metallic

- Silver white

- Silver white

- Silver

- Silver

- Silver

- Silver

- Silver gray

- Copper

- Brass

- Copper

- Transparent

- Black

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Transparent

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- Black

- White

- Gray

- Red

- Blue

- Green

- Yellow

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- SLA

- DLP

- SLA

- DLP

- SLA

- SLS

- MJF

- SLS

- FDM

- FDM

- FDM

- FDM

- FDM

- FDM

- FDM

- SLS

- FDM

- FDM

- FDM

- FDM

- SLM

- SLM

- SLM

- SLM

Support surface

Support surface

-

* Unit: mm

- SPI B-3

- SPI A-1

- SPI A-2

- SPI A-3

- SPI B-1

- SPI B-2

- SPI C-1

- SPI C-2

- SPI C-3

- SPI D-1

- SPI D-2

- SPI D-3

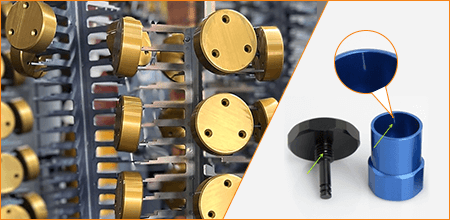

Discrepancy warning

Discrepancy warning

Due to the particularity and scarcity of the surface finish process, different batches of orders cannot be guaranteed to have the same finish. For example: Aluminum anodized color, there will be color difference more or less with each time, even though you choose the same opition of color.

If you need the totally same surface finish of batch products and samples, it is recommended to keep 1-2 samples at 3PCB, and then we can mass-produce the specified products according to the samples.

you can also add 0 surface treatments

Tapped Holes:

- No extra fee

- 3PCB will do the dimension and surface feature inspections based on the drawings provided by the customer.

- Pay extra

- 2D technical drawings are required.

- Pay extra

- 2D technical drawings are required.

- Pay extra

- 2D technical drawings are required.